What Does Best Dust Extractors Do?

Wiki Article

The Main Principles Of Best Dust Extractors

Table of ContentsThe Ultimate Guide To Best Dust ExtractorsBest Dust Extractors Can Be Fun For AnyoneUnknown Facts About Best Dust ExtractorsThe 3-Minute Rule for Best Dust ExtractorsBest Dust Extractors for DummiesThings about Best Dust ExtractorsThe Best Strategy To Use For Best Dust Extractors

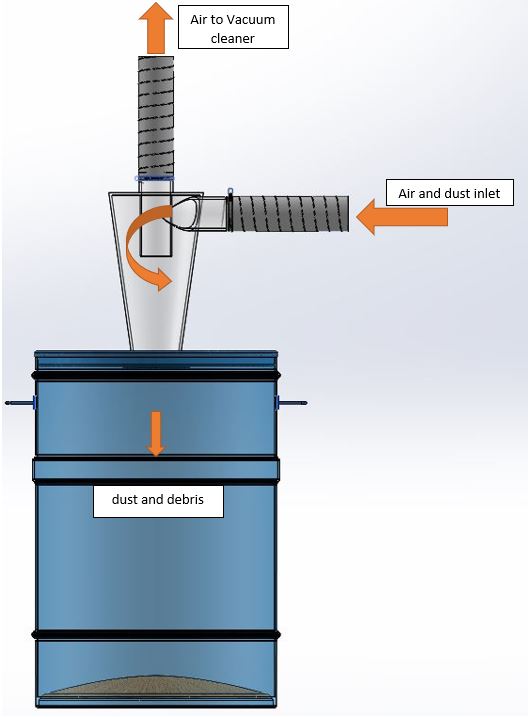

The CMAXX is a reverse pulse-jet cartridge dirt enthusiast. The ideal way to discuss what this indicates is to take place a scenic tour of the course that air adheres to via the dust collection system. Dirty air containing bits of dust enters the collector through the ductwork. Fans either push or draw the air through the ducts.As an outcome, this maintains the dust from hitting the filters at complete speed. At the bottom of this space, collected dust goes down out right into a drum or hopper.

In the CMAXX, these hang up and down from the tube sheet, which is the metal sheet dividing the filthy and tidy air areas. This makes the spaces that the air have to go with smaller.

Best Dust Extractors Fundamentals Explained

A few of it falls off. A few of it adheres to the filters. Gaskets at the top of each filter seal it to television sheet to maintain dust from slipping via. A pulse of compressed air impacts into the filters. Since the pulse of pressed air goes in the reverse direction of the routine air movement, we call it a reverse pulse-jet collector.The dust drops out of the collector as well as the filters are ready to accumulate even more dust. A pulse-jet collection agency is a really effective type of commercial dust collection system.

Differential pressure sensing units review the air stress on the filthy air and also tidy air sides of the filters. The dirtier the filters are, the more resistance they have to air going through them.

What Does Best Dust Extractors Do?

Utilizing differential pressure sensing units makes a pulse-jet dust collector extra effective because it reduces the usage of compressed air. It additionally aids the cartridge filters last longer, because the pulses of pressed air reason deterioration on them. Pulse-jet dust collection systems are efficient due to this filter cleaning.By making filters last longer, a pulse-jet enthusiast is the most inexpensive shop dirt collection system. Check out about offline cartridge filter cleaning. Cartridge collectors have the filters in either a horizontal or upright plan. In straight dust collection system layout, the filters lay on their sides and are piled on top of each other.

In a straight pulse-jet dust collection agency, the pulse cleansing causes dust to be blown off the filters. Because they're on top of each other, the dirt from the leading filters drops on top of the others. In a vertical pulse-jet collection agency, the dirt that pulses off of the filters goes down straight down into the hopper.

Everything about Best Dust Extractors

When comparing biscuits vs dowels the primary factor to consider is usually set you back. Yet woodworkers know joint stamina, speed of configuration as well as positioning simplicity are crucial factors to consider. Learn what joint is best for your projects in this overview.If you focus on metalworking, you already understand the importance of proper dirt collection. Not just can the metal contaminants launched throughout use a sander contaminate the air as well as dirty up your shop, yet they additionally have the possible to trigger harmful thermal events that can damage staff members as well as devices.

These devices gather steel grindings as well as store them in a protected containment room. To make certain that your dust collection procedure is as effective and secure as possible, you'll need to understand the best methods to operate and keep these indispensable devices. And also that's where we are available in. At Timesavers, we generate the very best woodworking and also metalworking completing equipments in the market.

Getting The Best Dust Extractors To Work

Since you have a solid understanding of the benefits of wet dust collectors, allow's dive a little bit deeper right into just how these equipments are made use of and also kept. To start, operators will connect their industrial grinding machine to the enthusiast via ductwork. These pipelines will deliver the airalong with any type of air-borne dustinto the damp dust collection agency, pushing them both straight right into the water storage tank.

After production ends, operators will certainly make use of a scoop to by hand draw debris up and out of the water container, leaving it got ready for the next run. Past these simple procedure actions, there are two vital variables that allow wet dirt enthusiasts to work correctly. Best Dust Extractors. CFM (cubic feet per min) determines the quantity of air being relocated, and fixed pressure (Inches of Water) is the pressure of the air being moved.

Have any type of additional inquiries concerning dust enthusiasts or steel completing in basic? You can also contact us if you would certainly like to discover even more about our dust collection machines as well as just how they can increase the effectiveness of your metalworking tasks.

The Basic Principles Of Best Dust Extractors

Dust is an issue in any type of interior area. The majority of dirt is also a flammable hazard that call for unique handling of the dirt.

NFPA 68 has actually considering that 2007 required all dust to be evaluated to determine the volatility visite site of the dust. If the dirt is not eruptive then the controls as stated above are not needed on dust collectors, as well as on dust enthusiasts under 8 cubic feet of the dirty side of the unit are excluded.

In 2015 2021 NFPA 652 mandated all business with dust collection systems to provide a Dust Dangers Evaluation DHA. This is a full analysis that consists of the dirt test as well as details dangers analysis for that plant as well as procedure. Generally done by a signed up engineer and can cost from $6000 to $20,000.

The Best Dust Extractors PDFs

How does an industrial dust collection system work? For a start, it is essential to note that there are different types of dust collection systems.Different sorts of filters and different levels and arrangements of air circulation or suction power are utilized to accomplish this. Typically, the dust from the cured air will certainly be captured or dropped in the filter as the air enters visit this site right here into contact with it. The dust will after that come under a sediment catcher or it will certainly Home Page be mechanically scrubbed, wiped, shaken, or pressed right into the debris collection area.

Then the air comes into call with a collection of angled items of metal called baffles which slow the air to avoid the dust from striking the filters at a speed that would certainly damage the filters. The air is then relocated into the plenum, which is another word for the sediment collector stated over.

Report this wiki page